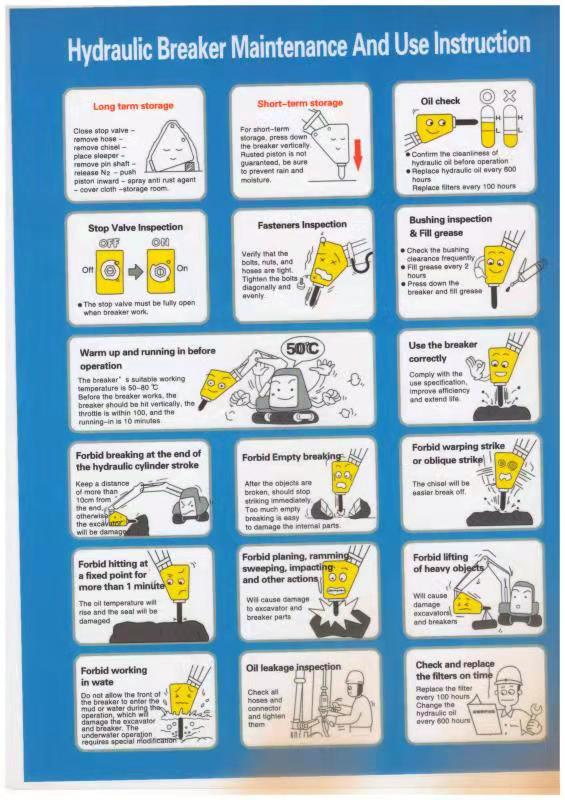

Hydraulic Breaker Maintenance And Use Instruction

Long term storage

Close stop valve - remove hose - remove chisel - place sleeper - remove pin shaft - release N₂- push piston inward - spray anti rust agent - cover cloth - storage room

Short-term storage

For short-term storage, press down the breaker vertically. Rusted piston is not guaranteed, be sure to prevent rain and moisture.

Oil check

Confirm the cleanliness of hydraulic oil before operation

Replace hydraulic oil every 600 hours

Replace filters every 100 hours

Stop Valve Inspection

The stop valve must be fully open when breaker work.

Fasteners Inspection

Verify that the bolts, nuts, and hoses are tight.

Tighten the bolts diagonally and evenly.

Bushing inspection & Fill grease

Check the bushing clearance frequently

Fill grease every 2 hours

Press down the breaker and fill grease

Warm up and running in before operation

The breaker’s suitable working temperature is 50-80 ℃

Before the breaker works, the breaker should be hit vertically, the throttle is within 100, and the running-in is 10 minutes.

Use the breaker correctly

Comply with the use specification, improve efficiency and extend life.

Forbid breaking at the end of the hydraulic cylinder stroke

Keep a distance of more than 10cm from the end, otherwise the excavator will be damaged

Forbid Empty breaking

After the objects are broken, should stop striking immediately. Too much empty breaking is easy to damage the internal parts

Forbid warping strike or oblique strike.

The chisel will be easier break off.

Forbid hitting at a fixed point for more than 1 minute

The oil temperature will rise and the seal will be damaged

Forbid planing, ramming, sweeping, impacting and other actions.

Will cause damage to excavator and breaker parts

Forbid lifting of heavy objects

Will cause damage excavators and breakers

Forbid working in water

Do not allow the front of the breaker to enter the mud or water during the operation, which will damage the excavator and breaker. The underwater operation requires special modification

Oil leakage inspection

Check all hoses and connector and tighten them

Check and replace the filters on time

Replace the filter every 100 hours

Change the hydraulic oil every 600 hours